FAQ - What's inside an LED light?

The amount of electronics housed inside an LED light depends on the fitting type. 12VAC MR16 retrofits and downlights with external drivers generally have much less circuitry housed within their base compared to GU10, B22 and E26/E27 retrofit globes.

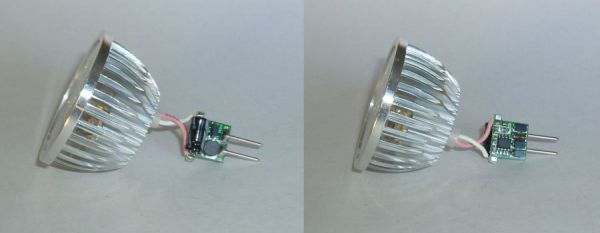

MR16s

LED MR16s downlights use the same 12VAC magnetic or electronic transformers as the halogen downlights they were designed to replace. As they accept an AC signal, rectification, i.e. converting AC into DC, of the 12VAC secondary output signal is necessary for proper driving of the LED light engine. This is usually achieved using a diode bridge. An electrolytic capacitor and voltage regulator IC are also present to manage the voltage variation for a steady, flicker-free light output.

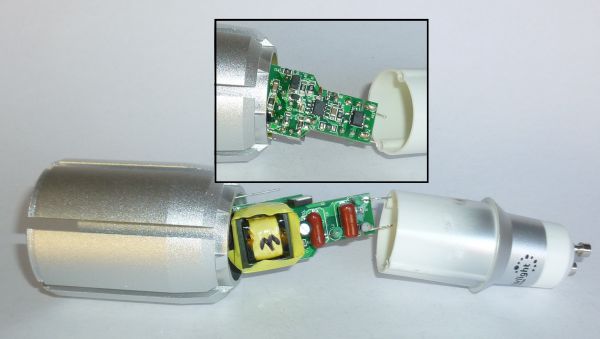

GU10s (Non-dimmable)

In the case of GU10s and other retrofit globes without an external driver/transformer, all driver circuitry is housed within the globe's base, resulting in a more densely populated board than that of MR16s. Potting compound is sometimes used in the base to isolate the electronics and reduce humming. The GU10's driver electronics would contain similar components to that of the MR16, space constraints perhaps favouring integrated chip packages over discrete components, and direct connection to AC mains necessitating an isolation transformer and components rated for higher voltages.

Downlight with external driver

In contrast to the above retrofit globes and downlights, LED downlights sold with external LED drivers house no electronics other than the actual light engine. A constant current (in the case of most downlight kits) is supplied via the LED driver output and connected directly to the LED light source. Potting compound is used to cover the wires for electrical isolation from the light housing.

Related Pages

- What types of light sockets are in use?

- What types of LED lights are available?

- What is the life expectancy of LEDs?

Back to FAQ index